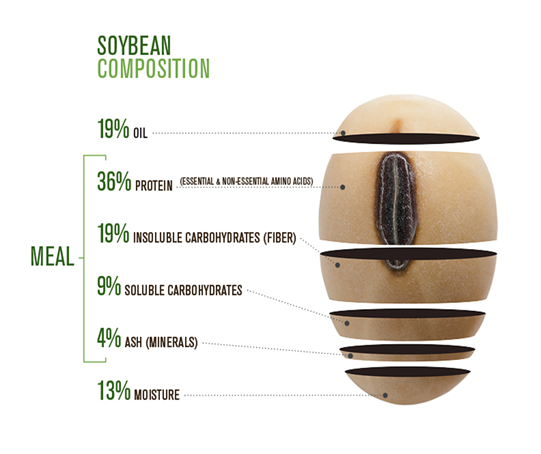

When soybeans are crushed, the three end products are oil, meal (protein) and hulls. And of the three, soy hulls have the least value. The crusher will blend some off in the meal and find other uses for them. But now science has found new uses, turning hulls into value-added products.

A lot of hulls are produced annually.  For example, the 2018 crop year is expected to crush over 2 billion U.S. bushels (120 billion lbs.), which will be a historical record. Soybeans contain 3 to 5 lbs. of hulls per bushel and a 2-billion-bushel crush (at 4 lbs. of hull per bu) will generate 80 million lbs. of hulls that need a place to go.

For example, the 2018 crop year is expected to crush over 2 billion U.S. bushels (120 billion lbs.), which will be a historical record. Soybeans contain 3 to 5 lbs. of hulls per bushel and a 2-billion-bushel crush (at 4 lbs. of hull per bu) will generate 80 million lbs. of hulls that need a place to go.

Soy hulls are the outer coating that is removed when soybeans are processed and is a fiber co-product used primarily by the livestock feed industry. You can learn more about the basics of using soy hulls in the feed industry by clicking here. Processors may blend hulls back into meal and create two classes, 48% high-pro and 44% low-pro meal. The 48% protein has little or no hulls. And occasionally, beef and dairy producers buy hulls to blend in with feed directly.

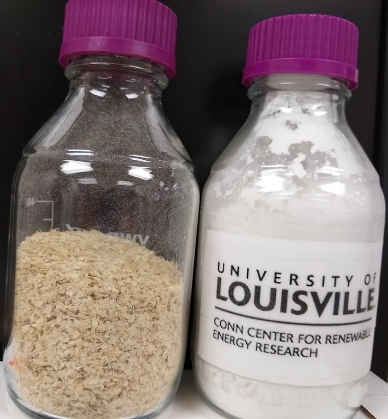

Jagannadh Satyavolu, scientist and theme leader with the Biomass and Biofuels Group at Conn Center for Renewable Energy Research, the University of Louisville in Kentucky, has had an interest in creating added value to soy hulls. “When I was with Cargill, we developed HemiForce enhanced fiber additives from soy hulls from our Cedar Rapids plant. In Louisville, we produce xylose (a low-calorie sugar) from the hulls. And currently we are working on carbons for multiple applications (including for lithium-ion batteries). We are also using modified soy hulls in polymer composite filaments for 3-D printing.”

Soy hulls contain primarily cellulose

xylose on the right (photo courtesy of Jagannadh

Satyavolu).

and hemicellulose along with some lignin and pectin that hold it all together. Satyavolu said the first step they take is selectively separating hemicellulose from the hulls. “From the hemicellulose we can extract and isolate xylose, a five-carbon, low-calorie sugar that can be used as a diabetic sweetener and help reduce obesity-related metabolic disorders. It can also be used to produce bioplastics and biofuels. Corn, rice and soy hulls are all good sources of xylose sugar with a commercial value of $3,000 per ton.”

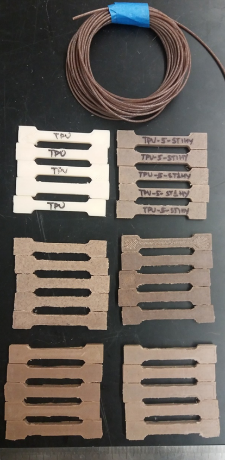

The remaining fiber is primarily cellulose, a very sustainable fiber with industrial uses. The United Soybean Board (USB) provided funds to study how to take these cellulose fibers and create a natural fiber polymer composite used for 3-D printing.

containing 10% modified soy hulls

(photo courtesy of Jagannadh

Satyavolu).

“Today’s lightweight composites use carbon fibers that are expensive. And the low molecular weight cellulose can be physically and/or chemically modified for polymer composites while improving strength, reducing weight and improving functionality of the fiber. Natural fibers from soy hulls reduce weight, cost less and are more sustainable.”

Lastly, the cellulose fiber fraction can be carbonized and activated, creating an activated carbon that is commonly used by industry. “It has a very high surface area of about 1000 square meters per gram of product. As activated carbon it can be used to capture and filter out impurities in products, it can be used in lithium-ion batteries or as fluency agent,” said Satyavolu. One possibility he suggested is combining Dust, a talc replacement made from a soybean meal protein isolate and carbons made from soy hulls to create an ideal fluency agent all made from soybean end products.

One of the most interesting possible applications is that the carbonized fiber becomes a natural active carbon in the soil to feed the soil microbes. Satyavolu said the carbonized fiber has many of the characteristics of biochar in the soil, improving soil quality without the recalcitrant characteristics of wood-based biochar

and then

and then